Precia molenXKV

XKV

The hopper system comprises:

- Feed structure with material layer height adjustment device and material detection sensor, extended by product guide edge strips. Belt seal flaps. Horizontal and lateral clearance angles on feed structure and edge strips to avoid any risk of jamming of the belt.

- Belt carrier system with braced modular frame comprising:

- Carrier roller train

- return roller

- smooth rubber belt with anti-abrasion coating (rapid replacement of the belt by lateral extraction at the side of the hopper). Belt characteristics (vulcanised endless) are defined by our technical department according to the materials to be handled

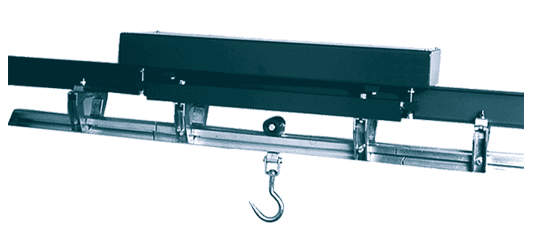

- belt replacement assistance device

- Two guide rollers

- Coated convex drive drum with bearing-mounted shaft

- Convex return drum with running hub

- Screw-operated belt tensioning device

- External scraper device placed under the external part of the belt level with the drive drum

- Internal scraper device placed in the return part of the belt

- Back-geared motor drive system comprising a variable speed synchronous motor (IP 55 – Class F) coupled to a hollow shaft reduction gear. This drive system is mounted on the end of the drive shaft (ungrounded)

- Safety device: Lateral protection systems with solid rear parts and lower grid parts

- Jetty structure

- Support base for handling

- Construction : hot galvanised steel